What is the production process of iron sheet printing T […]

What is the production process of iron sheet printing

The increasing variety of printing has driven the continuous innovation of printing equipment, printing technology, and printing process, and production techniques that meet the individual printing needs of users are emerging in endlessly. As far as printing materials are concerned, many categories can be listed, and iron sheet printing is one of them. What is iron sheet printing? What are the precautions for iron sheet printing production? Biyin Bazaar today will talk about what is iron sheet printing production process.

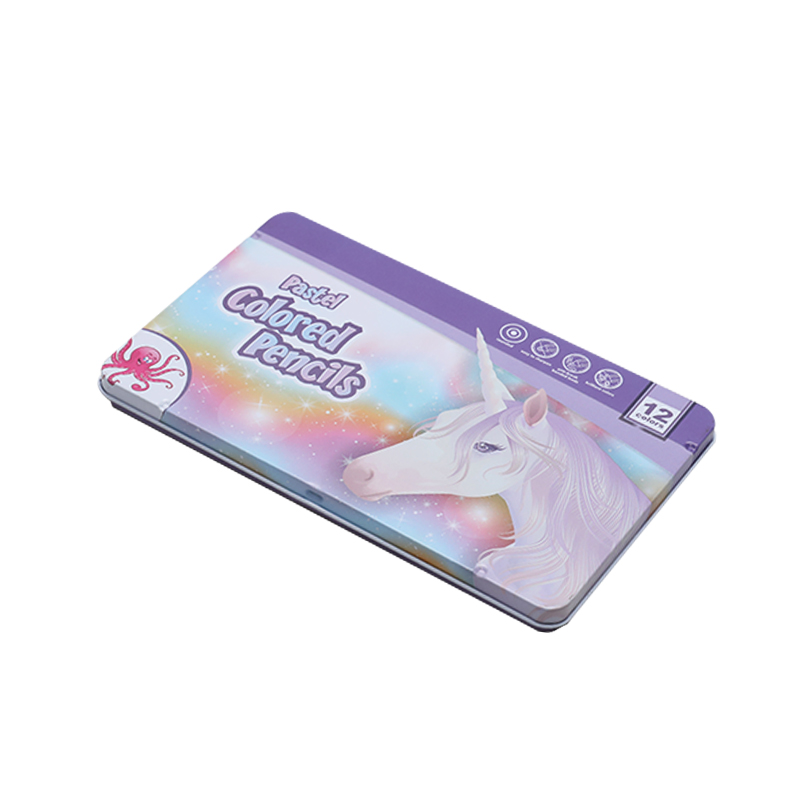

Iron sheet printing is printing on metal plates, so it is also called printing or metal printing. Generally, pictures and texts are printed on the surface of tinned iron or aluminum plates. Iron sheet printing products are mainly used in the manufacture of food packaging boxes, stationery boxes, children's toys and indoor decoration supplies.

Iron sheet printing uses hard metal substrates, which are easily worn out. Therefore, offset printing is used to transfer graphics and text through a blanket cylinder. Therefore, the structure of the printing press is basically the same as that of ordinary printing paper. However, The metal plate cannot be bent like paper and stuck on the impression cylinder, and can only pass horizontally between the blanket cylinder and the impression cylinder. In addition, the offset press for iron sheet printing must be equipped with a drying system.

The process of iron sheet printing is: iron sheet processing→printing→drying 1. Iron sheet processing. Before printing, use dilute alkali solution or alcohol to clean the dust and oil on the surface of the metal plate.

2. Printing. The surface of the metal plate is smooth and non-absorbent. Therefore, the ink for iron sheet printing must have good adhesion, and also have good heat resistance, light resistance, solvent resistance, cooking resistance and mechanical impact resistance. On the metal plate, it usually needs to be printed many times, and the base varnish is printed for the first time to protect the metal from corrosion. The second time, white ink is used to print the bottom layer to cover the color of the metal, and then the graphics and text are printed in sequence according to the printing color sequence. Finally, the gloss oil is printed to protect the printed graphics.

三. Drying The metal surface is not absorbent, so it is necessary to dry the ink every time it is printed. The drying method can use steam, infrared rays, electric heating, etc. The printed matter goes in from one end of the drying tunnel and completes drying when it comes out of the other end. The humidity of the drying tunnel is different depending on the printing ink, generally between 150-200℃. The temperature of the base varnish needs to be 200°C, and the drying temperature of the varnish is about 150°C. The temperature is too low, the drying is not thorough, the temperature is too high, the ink is discolored, and the mechanical properties are reduced.